Cleaning Tools & Technology | Educational Articles | How We Clean

Cotton String Mop vs Microfibre Flat Mop vs i-mop

"Mopping a floor can't be that hard, can it?"

Mopping is an ancient floor cleaning technique that has been used in the commercial cleaning business for many years. And although mopping isn’t going anywhere anytime soon, there have been major technological advancements regarding the equipment used to mop floors.

There are many different types of mops that can be used for commercial cleaning hard floors. However, based on our 27 years of experience in the cleaning industry, we will take a look at the 3 most common:

- Cotton String Mop (Conventional Mop and Bucket)

- Flat Mop (Microfibre)

- i-mop (Latest Technology)

At In-Tec, we are constantly asked at either the initial meeting or later in the relationship by clients, ‘what is the difference between a string, flat, and i-mop?’ This is a great question, and we understand the need to know the differences. As ultimately, one of these mops (depending on which you/we choose) will be used to clean your workspace.

In this article, we will go over the 4 factors to consider when choosing between a string, flat, and i-mop to help you select the best one for your workspace.

- Cleanliness

- Durability

- Cleaning Time

- Floor Dry Time

Cleanliness

Cotton string mop

A cotton string mop can clean, to an extent. Although the floor may look clean, it doesn’t mean that it actually is clean. A cotton string mop doesn’t necessarily remove dirt, in fact, it often pushes dirt and bacteria around and spreads it to other areas instead of picking it up. However, it can remove up to 35% to 40% of the dirt.

However, a cotton string mop is effective if, for example, there was a large greasy spill in an industrial complex. In this case, a microfibre flat mop would not be the best mop to use due to its small fibres.

A traditional mop and bucket can also be effective if the workspace is a dirty area, an example being a mechanics work area. But, a cotton mop wouldn't be the best choice to use in a bathroom or kitchen space as although string mops pick up dirt and bacteria, they tend to spread them around instead of trapping them.

Microfibre flat mop

Microfibre is made from a very fine blend of synthetic materials which allows it to capture and remove dirt, dust, and bacteria within the fibres. Microfibres are 100 times finer than human hair and a good quality microfibre should be less than 1 dtex in width (mass in grams for every 1,000 meters). The lower the dtex the microfibre has, the better job it will do in effectively cleaning workplace floors. As the fibres are extremely small, this creates a static effect where the microfibre can attract dirt and lock it in.

A microfibre mop can achieve the best results when only used with water. You might ask, ‘why is this?’ Well, due to the cloth’s unique fibre structure, it can remove 93% of viruses and 98% of bacteria from surfaces as well as up to 75% of dirt removal.

Microfibre flat mops are also effective in cleaning hard-to-reach areas such as corners that attract a large amount of dust. They also leave a streak-free shine on all surfaces – tiles, vinyl, floorboards, etc.

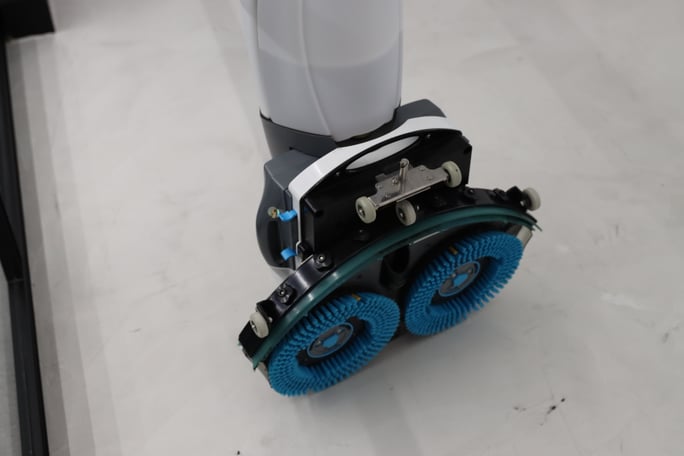

i-mop

The i-mop has a unique scrubbing power that can remove over 97% of dirt and leaves next to no dirty residue on the floor.

ATP (Adenosine Triphosphate) is found in all organic materials and provides energy to living cells. ATP tests can test the bacteria load counts on surfaces and is a highly efficient way to ensure cleaning procedures are working effectively.

ATP tests have confirmed that the i-mops deep scrubbing power cleans surfaces 90% better than a conventional mop and bucket and 20% better than a microfibre flat mop.

Durability

Cotton string mop

A string mop that is used daily on a site can last for no more than a month.

A string mop can be difficult to maintain. They tend to fall apart quickly and can be a pain to wash due to the plastic head. During the laundering process, the string mop tends to knot and shed strands easily which can result in a shorter life.

Cotton string mops can also leave behind fibres (lint) on your floors which can make your floor look dirty, especially if you have a floor type like non-slip tiles.

Generally, cotton mop heads can last between 15-30 washes before it needs to be replaced with a new one.

If acidic chemicals are ever needed when cleaning a commercial floor, cotton string mops are more durable than microfibre as some chemicals can break down microfibre, however using acids should always be the last point of call for daily or regular cleaning.

Microfibre flat mop

A microfibre mop that is used daily on a site can last for approximately 6 months.

They can be relatively easy to maintain, however, it will need to be washed properly. Microfibre needs to be washed at no less than 65 degrees for the entire wash cycle and can be used over and over again.

Unlike cotton string mops, microfibre flat mops are made from synthetic materials that remove the chances of linting.

A microfibre flat mop head can be removed and placed in the washing machine between 180-250 washes before it needs to be replaced.

A microfibre flat mop like one from Rubbermaid can last for a much longer time before the head needs to be swapped with a new one.

i-mop

At In-Tec, our oldest i-mop is 8 years old and is still going strong. Since its purchase, it has been used every day, and still has the same batteries and brushes – nothing has had to be replaced.

The maintenance needs of an i-mop are minimal. For instance, our oldest i-mop has only been in for a single service during its 8-year usage. Of course, there has been a need to replace squeegee blades, however these are not a large cost item and they can be changed by the onsite cleaner.

The i-mop can also be modified when new parts come out, such as the i-dose system that was released in late 2020 – so it has longevity.

Cleaning time

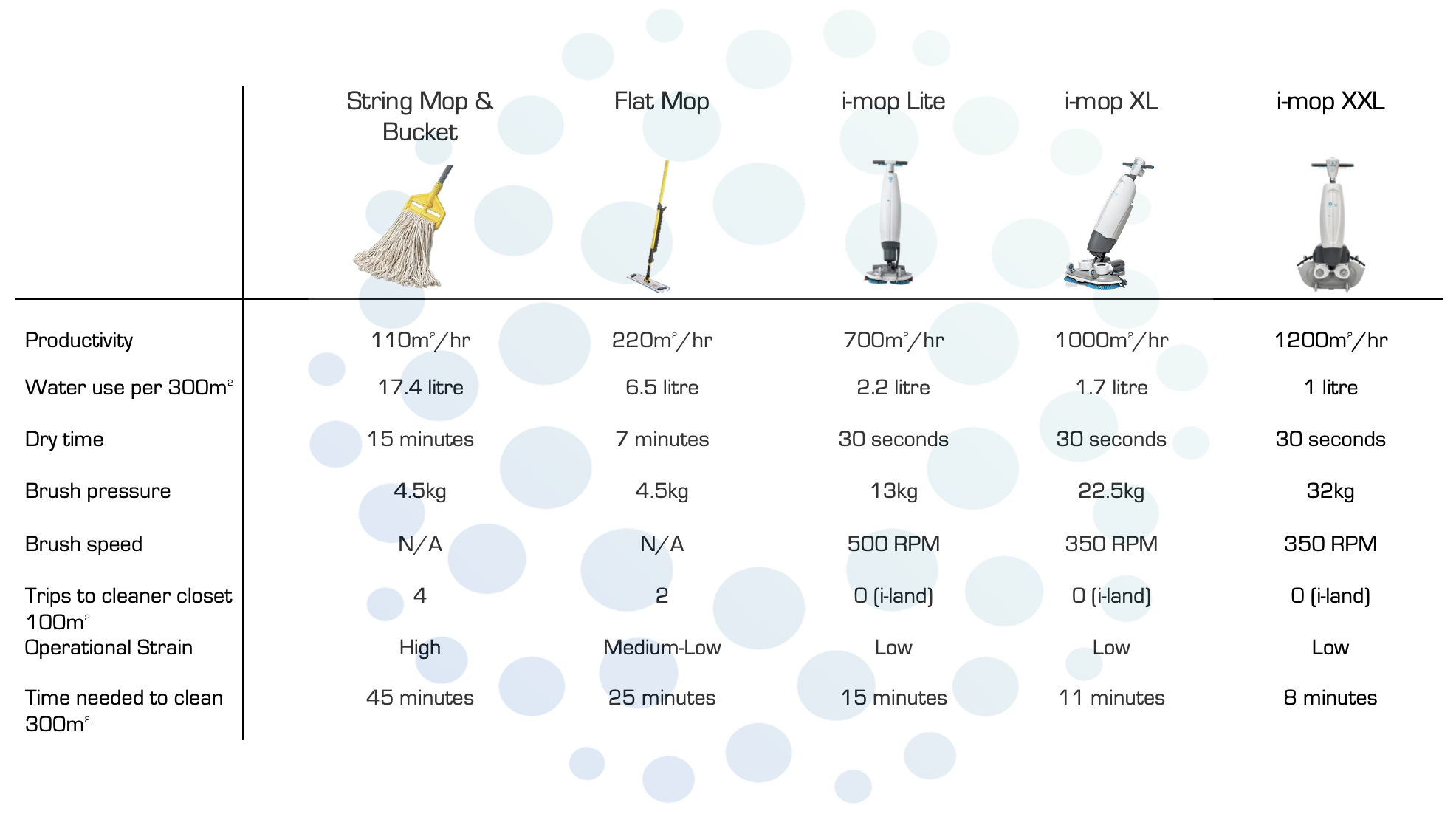

To give you a good idea of cleaning time, this section will look at how long each mop takes to clean a 300 sqm area.

Cotton string mop

A cotton string mop takes 45 minutes to clean a 300 sqm area.

Three factors influence this.

First, with a conventional mop and bucket, you have to constantly dunk the mop in the water and wring it out, which can take time.

You also need to constantly change the water in the bucket as it gets dirty. This most likely results in the cleaner having to take trips back and forth to the cleaning/storage room to re-fill the bucket from the sink.

The last factor that affects the 45-minute cleaning time is the operational strain of the string mop and bucket. Cotton string mops are 80% heavier than microfibre and can often be hard to manoeuvre due to the sheer weight which can slow the time it takes to clean an area.

Microfibre flat mop

The time it takes to clean a 300 sqm area with a microfibre flat mop is 25 minutes.

As the microfibre flat mops, such as those from Rubbermaid, are a bucket-less system, no time is wasted dunking the mop in the water and wringing it out.

A flat mop is more absorbent than a traditional string mop as the density of microfibre allows it to hold 6 times its weight in water.

i-mop

The i-mop is considerably faster than both the flat and string mop. It cleans up to 70% faster than a mop and bucket. The time to clean a 300 sqm area with the i-mop:

- i-mop Lite – 15 minutes

- i-mop XL – 11 minutes

- i-mop XXL – 8 minutes

Now, where the i-mop XL differs from the string mop is that it can hold up to 4 litres of water which can clean a 400 sqm area. Whereas the conventional mop and bucket can hold approximately 10 litres of water.

Due to the i-mops speed and manoeuvrability, a cleaner operating the machine will be able to clean at full walking speed, getting the job done quicker and at a better standard.

Floor dry time

Cotton string mop

A string mop has the slowest time of all 3 mops with a 15-minute dry time. This is because a string mop tends to distribute too much water unevenly along the floor which is why some areas take much longer to dry.

Consider this: A cleaner starts with a brand-new string mop, clean water, and the right amount of chemical in the bucket. What you’ll find is that when the cleaner starts mopping an area, the start of the mop will be too wet. It will then get to a certain stage where the mop has the right amount of moisture to remove the dirt – this is the only point when the string mop is doing its job. Then, the last stage is when the mop gets too dry to remove anything off the floor.

A floor that is too wet for too long is a breeding ground for bacteria. The bacteria count will actually increase rather than decrease.

Microfibre flat mop

The flat mop takes half the time to dry compared to the conventional string mop – 7 minutes.

A good commercial cleaner will pre-soak the microfibre mop before use. What this does is the microfibre is able to use the capillary action and soak up the water evenly throughout the whole head. So, when the mop is in use, it can spread water equally across the floor which results in a quicker dry time.

i-mop

The i-mop has a dry time within 10-30 seconds of cleaning due to advanced suction technology that can almost immediately extract all the water and cleaning solution off of the floor.

A string mop and flat mop can take anywhere between 7-15 minutes to dry. The period where the floor is wet is often called ‘hazard time.’ This stage is considered dangerous as workplace accidents such as slips and falls are a high possibility.

The i-mop reduces the ‘hazard time’ risk by 95%.

Data referenced in the comparison table is obtained from i-team global.

String mop vs flat mop vs i-mop: which should you choose?

When it comes to choosing a mop for your site, there are many different factors to take into account.

It all just depends on your individual needs and what you’re after.

Ask yourself these questions as a good starting point:

- How large is your workplace? (Square meterage)

- Does your workplace have a lot of hard-to-reach areas?

- What are you wanting the mopping to achieve? (The look of a clean floor or an actual clean floor)

- Are you fixed on paying a particular price for a mop?

- Do I have team members onsite when the cleaner is there? If so, do I want to have a quick floor dry time so my staff members aren’t walking on wet floors?

An important point to mention is that you don’t only need to choose one. Most sites at In-Tec will have a combination of a microfibre flat mop and an i-mop. This is because a flat mop can clean all the edges of a room and behind the toilet, whilst the i-mop takes care of the rest (the i-mop can only get within a centimetre of the edges).

Some sites, such as industrial complexes, will have a flat mop for the common areas such as kitchens and lunchrooms, and a string mop for certain areas that need a high scrubbing power.

To learn more or to ask questions about choosing a specific mop for your site, schedule a call with Paul.